Partnership, a word that is used often: but what does it mean for you?

Today more than ever before, the world is globalised and interconnected. As Italians we are increasingly dependent on foreign countries for the purchase of components - in terms of raw materials, Italy has always depended significantly on other countries - for production and manufacturing processes, but we also choose suppliers based on price and the quality and availability of components. This process has led to us depending more and more on distant countries, like China or other Far Eastern nations. One consequence of this has been a significant increase in the frequency of business travel between continents, with the supply of flights growing to meet demand. It has become possible to travel to the other end of the globe at costs that would have been unthinkable until relatively recently.

On the one hand, the spread of Covid-19 has shown us that it is not just the economy that is global – so too is the speed with which travellers can spread viruses to other parts of the world – on the other, we must now reflect on the consequences of a situation that has all the hallmarks of a severe economic crisis. Indeed, the health crisis is only the first emergency we will have to deal with and there is no doubt we will see a long-term impact.

One of the most interconnected sectors at a global level, the automotive sector, has been at the epicentre of the epidemic since it first emerged in Wuhan, in the province of Hubei. Few people had even heard of Wuhan and even less people know this province accounts for about 10% of China’s car manufacturing output. The closing of factories – operating with just-in-time systems - quickly extended to all of China and shut down the production of giants like Toyota and Volkswagen, but the consequences were also quickly felt in European factories as they too depend on Hubei for some of their components.

A few weeks later, in Codogno, Italy registered its first Covid-19 infection. Even in Italy, few people knew this town of some 15,000 inhabitants in the province of Lodi, and even less were aware that the area is home to almost 3,000 companies with a combined turnover of approximately 2.5 billion euro. These companies include MTA (Meccanotecnica Codognese) which employs more than 15 workers in its factories around the world and has a turnover of approximately 200 million. The main focus of its production is electric and electronic components (control units for headlights and control systems for traction and brakes). After the red zone was established on 22 February, all businesses had to suspend production and people were asked to stay at home. This forced shutdown meant there was a risk that manufacturers like FCA, PSA, Renault-Nissan, Daimler and BMW - to name but a few - would not receive their components and be forced to halt their own production in the near future. To avoid this scenario, MTA’s general manager entered into talks with the institutions and succeeded in avoiding a complete shutdown. Gradually, despite operating at a reduced capacity, the plant started up again and was able to supply other factories around the world that rely on components from Codogno - much to the relief of customers and workers in the other factories in Mexico, India and Brazil who risked losing their jobs.

Were you wondering why MTA’s customers didn’t simply replace it with another supplier? They were not able to because these control units are highly customised and are developed in collaboration with customers. Considering the volumes required, it would have taken up to two years to have a viable alternative.

That's why relationships with suppliers are crucial

This shows us clearly that supply chains are very often international and that situations like the one we are experiencing now represent an extreme example of the principle that a butterfly flapping its wings in Brazil can cause a tornado in Texas. And now we also know why replacing a supplier might not be so easy.

For these reasons we need to acknowledge the importance to relations with suppliers, just like we value relations with our customers, staff and the organisation. Given the criticalities associated with supplier relations, it is important to create genuine partnerships. To ensure the food supply chain runs smoothly – which means guaranteeing stocks are available for supermarkets in these troubled times – as well as actual food producers, the Italian government has had to allow food packaging companies and distributors to operate so that these products can reach our supermarket shelves and tables.

The success of a suppliers depends on organisations, but they also wield considerable power in exceptional times when there are shortages, as they can decide who to prioritise. If they are not able to serve customers as they would normally, they will establish who supplies go to, discriminating on the basis of the importance and strategic relevance of customers.

This underscores the importance of establishing continuous relations, based on collaborations over a long-term period.

Collaborations with suppliers can be interpreted in various ways. The us-and-them approach is often applied, but the us-us approach is more useful. Over time, the development of sustainable, mutually beneficial relations generates more than the sum of individual unilateral advantages. Moovs offers learning solutions to replace the us-them approach with effective methods for developing partnerships. This applies to the interaction with suppliers, the drafting of SLAs and the collaboration itself. Helping each other to maintain an advantage and mutually enjoying the success of every new contract.

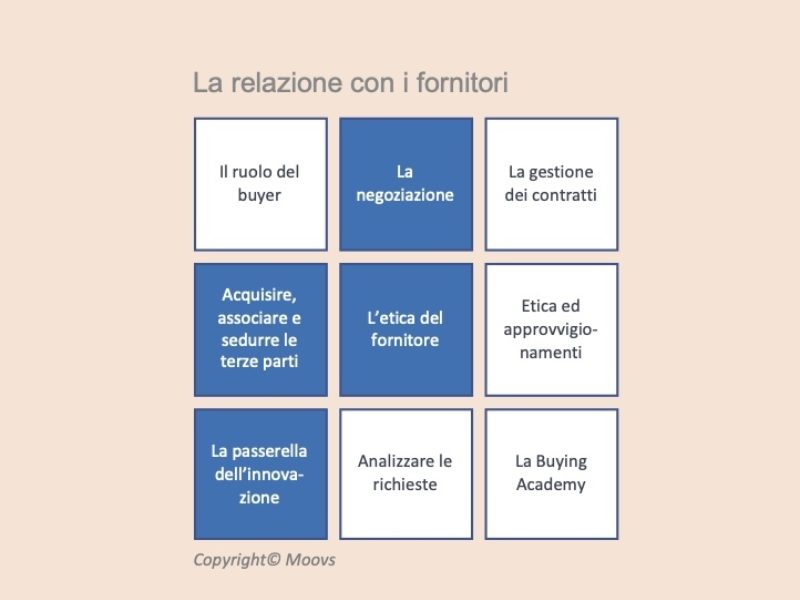

The role of buyers

Profit is not just the result of higher sales volumes. Cost control or reduction is just as important. A solid procurement policy is essential. What is the best price? Is the product of the right quality? Am I the only supplier or am I the best supplier? Can I negotiate on price without jeopardising a relationship? These are all key questions in the procurement process.

This course teaches how to negotiate during the procurement process and will allow you to learn techniques, determine your strategy and analyse suppliers, with an emphasis on how to influence them and make negotiations an integral part of company strategy. The results could be a reduction of costs and the optimisation or expansion of processes.

The negotiation

We negotiate much more than you might realise. In meetings, projects and conversations. As soon as interests are in play, the process of influencing your counterpart begins. There are also more “formal” occasions during which orders and contracts (e.g. collective labour agreements) have to be negotiated. There’s a great deal involved in a negotiation - from the preparatory phase to the negotiation itself and the tactic of directly influencing aspects such as content and ‘climate’ has an important role. The opinion you listen to will depend on the type of negotiation. Are we dealing with a long-term relationship, a turbulent relationship or a new one? How is the other party acting? Is there a high or low degree of dependence? How relevant is your personal impact? All of these aspects are examined in the course.

Contract Management

A long-term relationship, based on contracts spanning several years, requires constant monitoring of service levels as well as the management of exceptions and variables that occur during the execution of the contract. It also requires some effort to maintain the relationship and the use of escalation procedures for resolving any conflicts. This workshop illustrates good practices, discusses case studies and analyses real cases, with the involvement of organisational functions and roles involved in the management of contracts, looking at the required duties, processes and activities.

How to acquire, associate and involve third parties

More and more organisations work with external staff directly or through professional agencies. Flexibility is important if you want to be less vulnerable, have success in managing spikes in demand or for tying a small number of talented professionals to your organisation. However, if not correctly organised, this process could also expose you to financial risks. It is important to think how to motivate external (as well as permanent) staff as there are means to involve them and get them firmly on board so they remain loyal to your company.

Supplier ethics

The customer is king, and we want it to remain this way. We like to serve customers properly, carefully, quickly and at good prices. Customers are demanding and for good reason ... but perhaps not always? We like to satisfy procurement requests and negotiate our way through the myriad of existing offers. Avoiding stress is important but it also takes a great deal of effort. How can we do this effectively? Creating sustainable relations is an art and often involves taking difficult decisions and engaging in honest communication.

In this seminar we’ll be looking at how to make relations with customers more relaxing and how to run your business effectively.

Ethics and procurement (for buyers and employees of procurement companies)

The customer is king, and the buyer is in a position of strength with suppliers as the former determines who gets to serve the customer. Would you not agree? However, even if there are numerous suppliers, an individual supplier may have considerable power. Since customers can be judged by the conduct of their suppliers, good relations are important. This means asking questions like:

How can we select the right supplier from all the ones in the market? What is ethically correct?

What are the moral and qualitative requirements we set ourselves in terms of suppliers and how responsible are we if they subsequently fail to satisfy these requirements? How can we be sure we have enough correct information on a supplier (and their processes)?

Are we responsible for the conduct of our suppliers’ suppliers (i.e. sub-suppliers)?

Existing laws on conduct and ethics during tenders (tender processes, non-compete clauses) offer some guidance but managing these issues can be tricky. How do we go about it?

Can we prevent being directly or indirectly affected by an event like a pandemic and, if so, how?

How can we establish solid and careful ethics when it comes to procurement, to ensure we can look at ourselves in the mirror and be fully satisfied with our approach?

In this seminar we address these issues and prepare staff to deal with situations by assessing the contexts in which they operate and the implications of the decisions to be taken.

The catwalk of Innovation

Innovation is becoming increasingly important for retaining leadership. New ways of thinking, innovation workshops, incubators, thought-leaders, a start-up mentality, etc are needed for the world of tomorrow. All too often, companies simply tell suppliers the demands they have to satisfy. A classic example are tenders where there is often little room for creativity. However, the question is: do organisations, and more specifically buyers, really know what the future market trends are and what their customers want? In order to survive, suppliers have to keep up with the times and observe trends in order to surprise their customers. Organising a catwalk for innovation provides a stage for suppliers. This can also be extended to new suppliers or involve customers (co-creation).

The "Buying Academy"

Why is a "Buying Academy" necessary? Because this enables us to create a "way of working" which makes it possible to rapidly scale up volumes, while maintaining, or even increasing, speed. In terms of the management of risks, it is important for processes to be clearly defined. A homogeneous working approach will result in less errors, less time wasted and less need to involve senior staff. It leads to a manageable workload (fewer distractions, less duplication, etc). Clarity in processes, working methods and responsibilities leads to more control and results on the most important KPIs. Through a buying academy, employees will learn all aspects concerning procurement for their role, e.g. manager, purchaser, assistant, etc. The buying Academy will be the platform for the pre-onboarding and onboarding of new employees and will increase the competencies of existing employees in a cycle of continuous learning.

Conclusions

The relationships with suppliers, if based on clear partnership agreements, allow you to establish alliances able to favor the development of your organization (growing together) and to protect it in difficult situations (lack of supply or, on the contrary, need to select the supplier in the contraction phases).

If you want to deepen the training plan or want to submit a case for further information, contact us at the email address info@goodgoing.it. We will be happy to face with you the best ways to support you and thus help you achieve you.